ROBOT BASE PLATE WELDING AND DOOR CUTTING COMBINATION MACHINE

MODEL: RW-DC120/300

Application:

The welding system are applied for light pole base plate welding production. By real time communication between robot and welding power, according to different welding position to gain good quality welding seam,.

This machine has six major applications in the production of street light poles, as follows:

- CNC cut flat of the pole bottom ,

- Positioning and assembly of the bottom plate,

- Welding the inner and outer seams between the bottom plate and the pole,

- Welding the base plate stiffener,

- CNC electrical door cutting

- Door frame welding

Suitable for conical poles, round poles, octagonal poles, polygonal poles, equal diameter poles

Main parameter:

| NO. |

Item |

Parameter |

| 1 |

Pole min diameter |

120mm |

| 2 |

Pole max diameter |

300mm |

| 3 |

Pole max.length |

12m or 14m |

| 4 |

Pole min. thickness |

2.5mm |

| 5 |

Pole max. thickness |

For welding :12mm

For door cutting thickness 8mm, Option=12mm)

|

| 6 |

The maximum thickness of the expanded tube that can be deformed

|

8mm |

| 7 |

Pole max weight

|

standard:300kg

Option: 500kg

|

| 8 |

Max QTY of base plate stiffener

|

4~8

Note: If the quantity is large and the spacing of the stiffeners is small and the welding torch is affected, half of the stiffeners can be welded

|

| 9 |

Size of base plate stiffener

|

Normal street light poles and high mast are suitable

(Different sizes of stiffener require different molds, which can be processed and manufactured by the user in accordance with the mold provided in the machine)

|

| 10 |

Welding speed

|

Reference speed 300~500mm/min

Different thickness and different welding speed

|

| 11 |

Base plate shape

|

Circle, square, octagon, multiple sides of four sides |

| 12 |

Min thickness of base plate

|

10mm

Recommended value, too thin, difficult to weld inside and outside, easy to burn through)

|

| 13 |

Max thickness of base plate

|

Suitable for normal poles

|

| 14 |

Min size of base plate

|

150mm×150mm |

| 15 |

Max size of base plate

|

Diameter:500mm, or square plate 500x500.

Option: Diameter:700mm, or square plate 700x700.

|

| 16 |

Requirements for the consistency of the size of the stiffener and the base plate

|

Dimension tolerance is within 1mm

It is recommended to use laser cutting or plasma cutting to ensure the consistency of the size to obtain a better robot welding effect

|

| 17 |

Requirements for the size consistency of the door frame

|

Generally, the door frame is purchased from outside, and the size tolerance is more than 1mm.

Therefore, it is necessary to manually install the door frame, and after the spot welding is firmly (or after the clamping, the robot will weld again, if the tolerance is relatively small, it can also be directly welded by the robot

(Note: If the dimensional tolerance of the door frame is relatively large, it will cause the gap between the door frame and the door to be relatively large, leading to local leakage of welding, and local manual repair welding is required later)

|

| 18 |

Regarding the position of the switch plasma cutting,

The maximum distance from the highest point of the door to the base plate

|

1400mm |

| 19 |

Cutting type

|

Standard:pipe type cutting(3 axis)

Option flat surface type cutting + pipe type cutting (4 axis)

|

| 20 |

Door size and shape

|

There is no limit in the cutting range

|

| 21 |

Regarding the welding position of the door frame,The maximum distance from the highest point of the door to the base plate

|

2000mm |

| 22 |

Suitable for pole type

|

Conical poles, round poles, octagonal poles, polygonal shapes above octagonal, and equal diameter poles are all suitable

|

| 23 |

Plasma source

|

Hypertherm Powermax 45

(Made in USA)

|

| 24 |

Max perforation and quality cutting thickness

|

8mm(suggested value) |

| 25 |

Cutting speed

|

The cutting time of a door on a normal street light pole is 30~40 seconds |

| 26 |

CNC system

|

Si Dafeng(SF-2100S) |

| 27 |

Nesting SOFTWARE

|

SmartNest |

| 28 |

CNC Plasma cutting torch

|

1 set |

| 29 |

Arc voltage height controller

|

HEAVTH HP105 |

| 30 |

Height device

|

Plasma Torch height moving device, 1set

|

| 31 |

Production speed

(Including inner and outer welding of base plate, electric door cutting, door frame welding)

|

Normal street light pole: 12~16 minutes

5G pole: 40~45 minutes

The specific time depends on the size of the pole, the size of the stiffener, and the size of the door

|

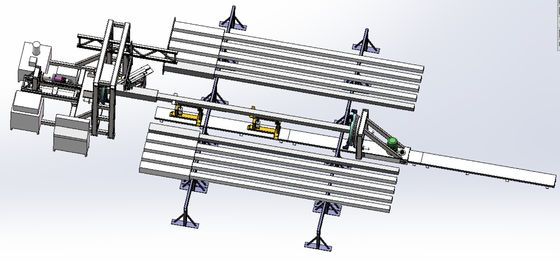

The general layout is as following:

Proprietary features:

- This machine integrates six functions, which can be completed in one loading and unloading. CNC cut flat of the pole bottom, the positioning and assembly of the base plate, the internal and external welding between the base plate and the pole, the welding of the bottom plate stiffener, the electrical door cutting , and the door frame welding . The material flow and loading and unloading time between independent processes are greatly reduced, and the production space is saved.

- With pole expansion function, eliminate the gap between the inner hole of the base plate and the pole, and realize automatic welding smoothly

- With the function of automatic placement and welding of the stiffener

- It adopts Japanese Kawasaki Heavy Industries robot with good operability and excellent quality.

- Adopting famous welding power source, good welding seam quality and high welding efficiency

- The positioner has a large turning angle, which can realize the most reasonable angle welding

- Beautiful welding shape and high reliability

- The CNC cutting of the light pole door , the cutting shape can be circle, square, rectangle, oval, etc. Any graphics that can be drawn by computer CAD can be cut by the special software that comes with the machine.

- The cutting source is automatic plasma, so the cutting speed will be very fast, and the cut will be smooth and round

- Due to the use of the Hypertherm Powermax plasma source and cutting gun, the cutting gap is relatively small, and the cut pieces can be used as door covers

- After the electric door is cut, if the door frame needs to be welded, the robot can complete the automatic welding of the door frame. And the door frame welding needs to be equipped with the laser positioning function

- The entire machine is designed in the form of a one-way assembly line. The poles are stacked on the left side of the machine. The operator can move one by one to the right to complete the welding, and the welded poles are stacked on the right. The pole moves and rises, no crane is required, and the labor intensity of the operator is low

- Save a lot of labor costs

- Can adapt to long hours of work throughout the day

Option Items:

Door cutting plasma: Hypertherm Powermax45,suggestion max. thickness 8mm. Option: Hypertherm Powermax65,suggestion max. thickness12mm.

The maximum pole diameter is 400mm, and square tube maximum size 350x350, the electric chuck inner diameter 620mm, suitable for 5G heavy pole (as 500kg) , Base plate max. diameter 700mm , or square base plate 700x700mm

3. flat surface type cutting + pipe type cutting (4 axis)

- On the square tube, there are 2 stiffeners on one side. A stiffener device is required, which can be moved up and down, suitable for different positions of the stiffener

- The laser positioning function is configured for welding the position and size of parts. The consistency is poor, about more then 1mm. Because the purchased door frame has the same size different, it is recommended that the door frame welded should be equipped with the laser positioning function.

- If the small end position is a square tube, the small end support cannot be rotated, and the support type needs to be changed. Add the 12-meter guide rail and the movable support of the small end to improve the accuracy of cutting and welding. It is suitable for round poles, square tubes, and octagonal poles. The small end support is servo synchronous rotation. In this way, it is no longer necessary to make a tooling fixture that turns square to round.

- pole bottom expansion tool

- stiffener tool

- Spare parts for Robot welding

- Spare parts for plasma cutting

- Networked production data system, the machine is connected to the Internet in the customer workshop,

Function (1):

can provide production management data: power on time, welding time, cutting time, non welding time, production quantity, etc

Function (2):

After the machine is connected to the Internet, the machine supplier can assist the customer in remote fault diagnosis and remote parameter adjustment. Convenient for customers to quickly resume production.

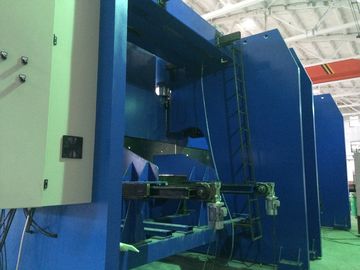

Similar photos

Robot welding system

1.Kawasaki Robot BA006N (Japanese brand)

BA series is a series of robots developed for welding specially. It is designed for welding specially. It is easy to operate and can achieve skilled welding operation through simple teaching operation. A touch LCD color display screen with excellent visual effect and easy operation is installed on the teaching device. Robot welding machine only need a cable connection, can classify welding conditions of storage, and one key call.

| Teaching methods |

Simple Operation Teaching AS Language Programming |

| Manner of execution |

Manual mode |

Independent axes, basic coordinate system and tool coordinate system |

| Reproduction mode |

Interpolation action of each axis/line and

arc

|

| Storage capacity |

|

8000 steps are equivalent |

| General signal |

External Operating Signal |

Emergency stop, external hold signal |

| Input and output |

32+32 |

Kawasaki BA series robots use E01 control cabinet, compact shape, suitable operation system, rich functions, easy maintenance and high scalability. 6.5 inch color LCD screen, touch screen 640 x 480 pixels. Backlighting is used to make the LCD screen easier to see. The operating system adopts WINDOWS CE. The drop-down menu is used for window display, which makes the editing process simple and easy

| Fuctions |

Standard arc welding |

|

Model

|

BA006N |

| Arm form |

Vertical multiple joints |

| DOF |

6 axis |

| Maximum load capacity(KG) |

6 |

|

Maximum range of action

[DEG]

|

JT1

电源线及控制线

|

±165 |

| JT2 |

+150~-90 |

| JT3 |

+45~-175 |

| JT4 |

±180 |

| JT5 |

±135 |

| JT6 |

±360 |

|

Maximum speed of action

[DEG/S]

|

JT1

电源线及控制线

|

240 |

| JT2 |

240 |

| JT3 |

220 |

| JT4 |

430 |

| JT5 |

430 |

| JT6 |

650 |

| Inertia[N.M] |

JT4 |

12 |

| JT5 |

12 |

| JT6 |

3.75 |

|

Inertial moment

[KG.M2]

|

JT4 |

0.4 |

| JT5 |

0.4 |

| JT6 |

0.07 |

| Repeated positioning accuracy [MM] |

±0.05 |

| Horizontal elongation [MM] |

1445 |

| Weight[KG] |

150 |

| Power capacity [KVA] |

3.0 |

| Installation mode |

Ground,Top loading |

| Installation environment |

Temperature |

0~45° |

| Humidity |

35~85%( No dew) |

| Vibration |

0.5G以下Less than 0.5 |

| Others |

Robot installation must be away from the interference of flammable or corrosive liquid or gas appliances |

| IP Level |

IP65 |

| Recommended Controller |

E01 |

Range of action

Introduction Collision Preventer of Welding Torch

The 350 welding torch system is a CO2 welding torch, which is commonly used for arc welding in Asia.

The replaceable gun neck welding gun system has the advantages of high rated value and high duty cycle: intelligent interface can realize fast maintenance and repeatable positioning functions, and shorten downtime

The welding gun system has a variety of gun necks and holders for all common machine joints to choose from.

Advantage

(1)Typical Asian CO2 welding design

(2)Replaceable gun neck can shorten equipment downtime and reduce maintenance and repair costs

(3) Optimal temperature characteristics ensure long service life of wearing parts

(4) High-quality cable assemblies ensure a long service life of the system

(5) Rugged welding torch structure can achieve high collision stability

| Model |

350 |

| Cooling way |

Air |

| Duty cycle |

100% |

| Rated value |

350A CO2 |

| 300A (mixed composition) |

| Wire diameter |

0.8-1.4mm |

| Welding gun neck |

35° |

NBC-350RL Welding Power System

Device Description:

The NBC-350RL robot special welding machine has two welding modes: low spatter and constant pressure, which can realize carbon steel rich argon and CO2 gas shielded welding. This product adopts an all-digital control method, which is highly adaptable and can communicate with the arc welding robot through a digital/analog interface.

Performance characteristics

(1)Can be matched with Kawasaki robot

(2)Numerous types of digital interface control can directly call the welding parameters stored by the customer

(3)Very small welding spatter, beautiful welding seam shape

(4)Optimized arc ignition, arc closing and ball removal functions

The fully digital control system realizes precise control of the welding process and stable arc length.

Powerful digital error reporting function, a variety of faults have error codes to display.

The system has a built-in welding expert database and automatic and intelligent parameter combination.

Friendly operation interface, unified adjustment mode, easy to master.

Soft-switching inverter technology, the whole machine is highly reliable, energy-saving and electricity-saving.

Welding power parameters

| No. |

Item |

Parameters |

| 1 |

Rated input voltage/frequency

|

380V±25% 3P/50Hz |

| 2 |

( KVA)Rated input capacity |

14 |

| 3 |

(A)Rated input current (A) |

21 |

| 4 |

(V)Rated output voltage (V) |

31.5 |

| 5 |

(%)Rated load duration (%) |

60% |

| 6 |

(V)Output no-load voltage (V) |

96 |

| 7 |

(A/V)Output current/voltage range (A/V)

|

60A/17V~350A/31.5V |

| 8 |

(mm)Welding wire diameter (mm) |

0.8,1.0,1.2 |

| 9 |

Wire feed type |

Push wire |

| 10 |

(L/min)Air flow rate (L/min) |

15~20 |

| 11 |

Torch cooling method |

Air cooling |

| 12 |

Enclosure rating |

IP23 |

| 13 |

Insulation class |

H |

| 14 |

L*W*H (cm)

Dimensions L*W*H (cm)

|

66*32*56 |

| 15 |

(Kg)Weight |

55 |

| 16 |

EMC emission level |

A |

Option:Gun cleaning, wire cutting and silicone oil spray device

As the picture shows. The gun cleaning and silicone oil spraying device is used to clean the splash in the nozzle of the welding torch and spray anti-splash silicone oil into the nozzle. The wire cutting device is used to cut off the small ball at the tip of the welding wire and ensure that the dry elongation of the welding wire is consistent, to ensure the success rate of arc starting and the stability of the welding process, as well as the accuracy of the detection at the beginning.

Operating environment

1,Grounding: C grounding, grounding resistance less than 10 ohms.

2,Welding wire: disc-mounted wire

3,Use of environmental conditions (indoor)

Ambient temperature:-5℃~40℃.

Relative humidity:≤80%..No dew

Programming and Workflow

Programming flow

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!