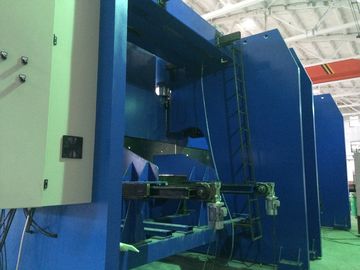

Water Cooling 0.2mm - 3mm 9KW Robot welding cutting machine,robot laser welding machine

Extra Large Payload Robots

M Series Robots (350-700 kg)

HIGH WRIST TORQUE ROBOTS

The M Series maximum payload robots incorporate a compact profile design with long reach and high wrist torque. With an impressive payload capacity of up to 700 kg, the innovative robot line design gives it the power to lift and manipulate heavy loads with great ease and high accuracy.

Typical Applications:

Machine Tending

Material Handling

M Series Robots:

Click on a robot below to learn more. Note: images not shown to scale.

MX350L

Payload :350 kg

Axes :6

Reach :3,018 mm

Repeatability :±0.5 mm

MX350L

MX420L

Payload :420 kg

Axes :6

Reach :2,778 mm

Repeatability :±0.5 mm

MX420L

MX500N

Payload :500 kg

Axes :6

Reach :2,540 mm

Repeatability :±0.5 mm

MX500N

MX700N

Payload :700 kg

Axes :6

Reach :2,540 mm

Repeatability :±0.5 mm

MX700N

MT400N

Payload :400 kg

Axes :6

Reach :3,503 mm

Repeatability :±0.5 mm

MT400N

DOWNLOAD

Kawasaki M Series robots brochure

COMPACT PROFILE

Conventional high-payload robots require a large counter-balance weight which can cause interference in the work zone as well as limit the overall working range of the robot. Kawasaki's innovative Advanced Link Structure design for JT3 up and down arm movement eliminates the need for this counter-balance thereby reducing interference and increasing work envelope.

ULTRA HIGH WRIST TORQUE

Using advanced engineering techniques in motor technology, the robot is capable of industry-leading wrist torques of 5,488 N.m. This high wrist torque provides the ability to significantly offset heavy payloads from the tool mounting flange.

MODULAR ARM DESIGN

All four MXE floor mounted robots use a common platform with a modular arm extension allowing the robots to be retrofitted in the field to either increase reach or payload.

PROGRAMMING FLEXIBILITY

M Series Robots can be programmed in two ways, via the robot teach pendant or a computer, and using one of the two Kawasaki's programming methodologies, Block Step or AS Language. The Block Step programming method eliminates time consuming program teaching with auto-path generating software. The powerful AS Language provides ultimate flexibility via any word processor text file and enables the programmer to create advanced logic, manipulate program locations, integrate peripheral components and control the application process.

Applicable materials:

Used for carbon steel, stainless steel, alloy steel, aluminum and alloys (copper and alloys, titanium and alloys, nickel-molybdenum alloys) and dissimilar metal parts. (Copper-nickel, nickel-titanium, copper-titanium, titanium-molybdenum, brass-Copper)

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!