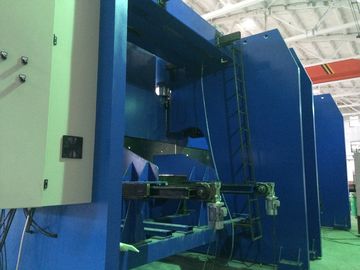

ET 6X1600 Slitting Machine For Light Pole Machine To Get One Side Bigger One Side Smaller Plate

Quick Detail:

| Name |

Other name |

Brand Name |

CMC |

| Steel plate slitting machine for light pole |

Ladder shaped plate cutting machine,

Light pole cutting machine,

Slitting machine

|

Feature |

Our line can cut the scrap edge of the steel sheet, cut one piece into 3 piece, and get one small size and one big size width |

| Cutting capacity |

2-6mm in thickness

12000mm in length

800-1600mm in width

|

Usage Industrial |

Street light pole industrial |

Description:

The light pole plate slitting machine is base on the rolling shearing principle.

There are two precess step on the machine:

First step is to cut the scrap edge of the hot rolled steel to get the exact width and good edge which is good for light pole seam welding process.

There is a dolly in the front of the slitting unit. It is for control the straight cutting.

Second step is to cutting the light pole taper steel and get one side big one side small width steel plate.

There is a dolly in the cof the slitting unit. It is for control the taper cutting degree. Through changing the base position on dolly to change the taper degree.

Application:

It is for light pole material to cut the scrap edge of the sheet two sides, and slitting the sheet into 3 pieces or 2 pieces to get one side small and one side big width.

Specifications

| TECHNICAL FEATURES |

| Name |

Unit |

Value |

| Max. Cutting Thickness |

Mm |

2.5~6 |

| Max.plate width |

Mm |

1600 |

| Max. inner Width of double slitting unit |

Mm |

1600 |

| Max. inner Width of taper slitting unit |

Mm |

1800 |

| Max. Cutting Length |

Mm |

12000 or 14000

(according requirments)

|

| Slitting speed |

m/min. |

12 |

| Power of the motor |

Kw |

5.5+5.5 |

| Overall size |

40x3m( for 12m light pole),

or 46x3m( for 14m light pole)

|

What is the difference with our cut to length and steel plate slitting machine?

The cut to length is suitable for the material: steel coil, while the steel plate slitting machine is for the metal sheet. Therefore, if the customers have many orders, then we suggest customer to buy steel coil, if less quantity and small budget, then clients can buy metal sheet from market directly.

Communication with customers

A: How to guarantee the cutting rate?

B: In fact, the work can measure the size and make mark on the sheet, then the position of the stopper on dolly to control the taper slitting rage.

How about speed of this machine?

It can reach 12m / min. It means we can get two poles material in one min.

How long is your quality guarantee period

One year. And when the machine arrives at customer workshop, we will send engineer to commissioning machine and give training. But also, the client can let their engineer to our workshop to study before delivery.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!