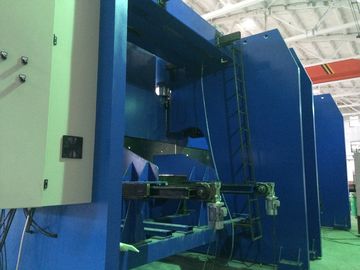

CNC POLE SHUT- WELDING MACHINE,

Model: HM2500/13000

Designed for Monopole, highmast pole, 5G communication pole

Diameter range:500~2500mm, Thickness:normally , 6~20mm, Length:13000mm

Note: the machine also can do more thickness, if thickness 18~25mm, suggestion process : do first shut welding , then do surface welding.

double arc three wire welding machine

Scope of application: suitable for large length medium size pole longitudinal automatic closing welding, like 5G pole, monopole, highmast pole

CNC POLE SHUT-WELDING MACHINE , it is suitable for one shell or two shell type polygonal and circle taper pole(Conical pole). it is automatic welding line, the gantry type structure is fixed and with welding system, V-shaped fully pole length dolly(worktable) with servo motor for speed adjustable moving , The hydraulic cylinder push the clamping wheel to close the pole and do welding at same time.

For two seam pole, when first seam welding finished, the bottom roller will rise and rotate the pole to another seam position to start second seam welding.

Proprietary features:

1.CNC automatic adjustment, CNC system, with the change of pole diameter, automatically adjust the pressure, automatically adjust the presser foot position, automatically match the feeding speed and position, keep the welding seam always in the closed state, to ensure the smooth welding.

2.Special CNC control system makes the left and right side of the foot synchronization performance is very good

3.On the basis of the qualification of the previous process, after welding, there is no torsion of the pole weld, and there is no need for personnel to pry and twist the rod at the back of the machine to center the weld.

4.The pole is on the V-shaped worktable, and its motion is servo controlled to ensure the stability of head and tail welding. Welding from head to tail greatly reduces the length of the tail that is not welded.

5.The number of clamping roller is 3 sets, the advantage is reduce the roller pressure to the pole surface , and reduce the scratch on the surface . It is suitable for the production of octagonal pole, polygonal pole and conical pole. It can be equal diameter or conical.

6.The V-shaped worktable(dolly) with motorized fast returning back function, and it reduces the labor intensity of operators.

7.Submerged arc welding function

8.With pole back guiding device,it can be adjusted adaptively. In practical operation, the position of welding seam is seldom adjusted, which reduces the labor intensity of operators.

9.Through the camera installed on the machine head, the welding seam is reflected on the screen of main control panel, making the tracking of the welding seam simple and easy, and reducing the labor intensity of the operator for monitoring of the welding..

10.The self-developed oil pressure and CNC system, making the welded pole round and deformation small.

11.For two seam pole, when first seam welding finished, the bottom roller will rise and rotate the pole to another seam position to start second seam welding

12.loading and unloading in the front position

13.The inner copper blocks, which greatly improves the welding penetration rate. Copper block contains cooling water

14.Operator: 1 person.

15.Optional items:

15.1 for plate thickness greater than 10mm, adopt double arc and double wire (or double electric and three wire) submerged arc welding, DC + AC, DC welding adopts high current and low voltage, DC arc obtains large penetration, AC adopts relatively small current and high arc voltage, increases fusion width, and obtains beautiful weld formation. Double the welding speed, improve the weld performance and reduce the power consumption..

15.2networked system

Function: timely update the software to obtain the best and latest software and experience data, which can assist customers in remote fault diagnosis and remote parameter adjustment. It is convenient for customers to quickly resume production.15.3Spare parts with machine .

The machine consists of the following parts:

- Servo driven V-type worktable (Dolly)

- Front and rear rails for V table

- Main gantry frame

- Drive system for V-type worktable

- Hydraulic clamping Unit( Including clamping rollers)

- Submerged arc welding system, with wire feeding system

- Flux recovery system

- Inner copper bar with water cooling system

- operating platform

- Pole rotation Roller, 2 pairs,on trolly

- Hydraulic system

- Control system

| Technical parameter |

| 1 |

Diameter of pole |

500-2500mm |

| 2 |

Worktable length |

13000 mm |

| 3 |

Thickness of pole |

6~20mm,Q235, Q355

Note: the machine also can do more thickness, if thickness 18~25mm, suggestion process : do first shut welding , then do surface welding.

|

| 4 |

Clamping feet quantity |

3 units |

| 5 |

Motor power of oil pump |

3+3 KW |

| 6 |

Servo motor power for V-type worktable (dolly)- |

7KW,Speed adjustable, AC servo |

| 7 |

Vertical pressing stroke |

2000mm |

| 8 |

Operating height |

The distance from the bottom angle of the pole to the ground:800 |

| 9 |

Welder |

Double electric three wire submerged arc welding machine

DC submerged arc welding power supply model 1250

Input power AC380V, three-phase, 50Hz

Rated input capacity 80KVA

Output current dc250a ~ dc1250a

Rated load duration 80%

AC submerged arc welding power supply model 1000A

Rated input capacity: 125kva

Input power AC380V, single phase, 50Hz

Voltage output range: 30 ~ 44V

Output current ac250a ~ ac1250a, rated load duration 60%

Double electric three wire welder brand: Kaiyuan

|

| 10 |

Welding wire diameter |

Double power three wire: single wire: 4.0, double wire: 2x1.6 |

| 11 |

Welding speed |

0.3 ~ 1.5m/min stepless adjustable

Note: different thickness, different speed)

|

| 12 |

Welding direction |

Welding from big end to small end |

| 13 |

Welding penetration rate |

80~90 % |

| 14 |

Electrical components |

Schneider (French brand) |

| 15 |

CNC system PLC |

Siemens (Germany brand) |

| 16 |

V-type worktable (Dolly) motor |

Servo motor |

| 17 |

Welder brand |

as item 9 |

| 18 |

Weight |

25 Ton |

| 19 |

Dimensions |

31000x7000x6200 mm (LXWXH ) |

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!