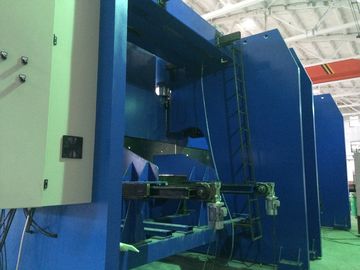

CNC 5G POLE SHUT-WELDING MACHINE

MODEL: HM500/12000

Design for Monopole, highmast, 5G pole

Roller type

Special designed for monopole,highmast pole, 5G communication pole,and normal street light pole

Standard:Diameter range:200~500mm, Thickness:4~12mm, Length:12m

Option:Diameter range:60~500mm, Thickness:3~12mm, Length:12m

Standard single arc single wire submerged arc welding machine

Scope of application:

Scope of application: suitable for large length medium size pole longitudinal automatic closing welding, like 5G pole, monopole, highmast pole and normal street light pole

This machine is usually suitable for welding medium size polygonal and conical pole, especially suitable for the pole which only has one seam. It’s an automatic welding line. The trolley is equipped with adjustable speed motor, which can pull the pole to move. The hydraulic cylinder makes the pressure wheel tighten the pole and weld at the same time.

Proprietary features:

1.CNC automatic adjustment, CNC system, with the change of pole diameter, automatically adjust the pressure, automatically adjust the presser foot position, automatically match the feeding speed and position, keep the welding seam always in the closed state, to ensure the smooth welding.

2.On the basis of the qualification of the previous process, after welding, there is no torsion of the pole weld, and there is no need for personnel to pry and twist the rod at the back of the machine to center the weld.

3.The driving pole is controlled by frequency conversion, with electric brake stop function to ensure the stability of head and tail welding,this system can weld the pole from small end to bottom end full area and almost no left length out of welding. This way is reduced the manual working of the next process.

4.The number of clamping roller is 3 sets, the advantage is reduce the roller pressure to the pole surface , and reduce the scratch on the surface . It is suitable for the production of octagonal pole, polygonal pole and conical pole. It can be equal diameter or conical.

5.The pushing type trolley with motorized fast returning back function, no need operator to push back manually and it reduces the labor intensity of operators.

6.The rear push trolly with pneumatic clamping device, It’s simple and fast compared with manual clamping.

7.The unloading side is roller type, which is convenient for loading and unloading, and is conducive to realize the automation of upstream and downstream materials. The loading and unloading can be on same side to make operator avoid the long-distance movement. The operator only need to work in the position of the host machine, which greatly reduces the labor intensity.

8.The self-developed oil pressure and control synchronization system reduces the requirements for the pole, making the pole after welding more rounded and less deformed.

9.Operator: 1 person.

10.Unloading roller rack,5 sets(suitable for 12,14m pole)

11.According to the layout of the buyer’s workshop, machines with different working directions can be provided

12.For the special requirements of customers, machine can be specially designed and manufactured to meet different poles all over the world

13.Through the camera installed on the machine head, the welding seam is reflected on the screen of main control panel, making the tracking of the welding seam simple and easy, and reducing the labor intensity of the operator for monitoring of the welding.

14.Option:Diameter range:60~500mm, Thickness:3~12mm, Length:12mm

The machine consists of the following parts:

1. Long worktable for trolley moving

2. Main gantry frame

3. Trolley drive system

4. Unloading roller rack,5 sets(suitable for 12,14m pole)

5. Hydraulic clamping part(Including clamping rollers, suitable for medium size pole)

6. Submerged arc welding system, with wire feeding system

7. Flux recovery system

8. Hydraulic system

9. Control system

10. Camera, welding seam monitoring system

11. Clamping roller, in accordance with customer's pole requirements.

With 1 set suitable for monopole High mast , 5G pole mold.

Optional: 1 set suitable for normal street light poles,minimum diameter of 60mm(round poles and conical pole)

Optional: 1 set suitable for normal street light poles, minimum diameter of 60mm(octagonal pole)

Optional: A set of rear clamping devices suitable for normal street light poles . (Includes a small tool, suitable for poles with very short length, such as 1~2 meters long arm)

| Technical parameter |

| 1 |

Diameter of pole |

200-500mm standard

60~500mm Option

|

| 2 |

Worktable length |

12000 mm |

| 3 |

Thickness of pole |

3~12mm, Q235, Q345

(Meet 100 diameter, 6mm thickness, meet 80 diameter, 5.5mm thickness)

|

| 4 |

Clamping feet quantity |

3 units. |

| 5 |

Motor power of oil pump |

4+4 KW |

| 6 |

Mobile motor power |

4KW. Speed adjustable |

| 7 |

Vertical pressing stroke |

500mm |

| 8 |

Operating height |

The distance from the bottom angle of the pole to the ground:850mm |

| 9 |

Welding machine |

1000A,Submerged arc welding

Standard configuration:Single arc single wire,

|

| 10 |

Welding wire diameter |

2mm, 3.2mm ,Welding wire diameter is subject to the thickness of poles. |

| 11 |

Welding speed |

0.8~3.0m/min stepless adjustable

Note: different thickness, different speed)

|

| 12 |

Welding penetration rate |

80 % |

| 13 |

Electrical components |

Schneider (French brand) |

| 14 |

CNC system PLC |

Siemens (Germany brand) |

| 15 |

Welding machine brand |

HUAYUAN ,Chinese brand |

| 16 |

Weight |

8 Ton |

| 17 |

Dimensions |

27000x3500x4500 mm (LXWXH) |

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!