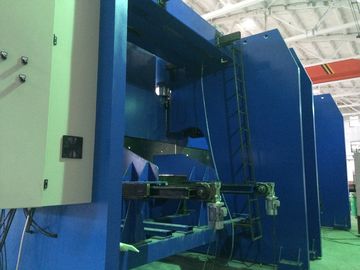

Application range:

1. Mainly suitable for Monopole, smart poles, 5G poles, power poles, highmast pole, with relatively large diameter and thicker thickness

2. Function 1: Straighten the some pole after longitudinal welding.

3. Function 2: After bending, the two pieces are joined by the upper and side cylinders, and then spot welding is performed manually, which is convenient for the next welding process.

4. Function 3: It is a complete circle for the welded pole, which is convenient for assembling the flange.

MAIN TECHNICAL FEATURES

| No. |

Item |

Unit |

Value |

| 1 |

Model |

|

HJZ-2200 |

| 2 |

Max, diameter of the pole

|

mm |

2200 |

| 3 |

Working force of top hydraulic cylinder |

KN |

1200 |

| 4 |

Max stroke of top hydraulic cylinder |

Mm |

850 |

| 5 |

Max distance from pinton rod to worktable |

Mm |

2200 |

| 6 |

Two-side cylinder output force |

KN |

300X2 |

| 7 |

Side cylinder stroke |

mm |

600 |

| 8 |

Movement distance from upper to lower for two-side cylinder |

mm |

1000 |

| 9 |

Max working pressure |

MPa |

21 |

| 10 |

Height above ground of worktable |

mm |

350 |

| 11 |

Column inner distance |

mm |

2400 |

| 12 |

Total motor power |

kW |

7.5+3 |

| 13 |

Weight |

kg |

10000 |

| 14 |

Main part Overall size |

mm |

1600*3500*2800 |

| |

|

|

|

Technical explain:

1. This machine has a three-beam workbench structure, and the oil cylinder is installed in the center of the upper beam and runs up and down.

2. The cylinders on both sides are installed on both sides of the main engine, and the side cylinders can be operated up and down through the structure of the motor screw rod.

3. All actions are jogging, that is, pressing the corresponding button will have the corresponding action, and it will stop after releasing it. The cylinders on both sides can act simultaneously or separately. .

4. Install two sets of supporting roller devices at the front and back positions of the worktable of the machine to facilitate the movement of the workpiece back and forth.

5. The front and rear supporting wheels are equipped with spring devices. When the rod moves axially, the spring supports the rod and can move freely. When the cylinder is pressed down, the pressure acts on the spring, the spring is compressed, and the rod face is close to the V-shaped block. Straight pole.

6. The main oil cylinder and the side oil cylinders have separate oil circuits, which do not interfere with each other and will not lose pressure.

7. With wireless remote control operation handle,

8. Polyurethane covering to prevent indentation

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!