Two Waves and Three Waves Highway Guardrail Roll Forming Machine

I.Basic machine parameters

- Mechanical properties and specifications of raw materials

Material: Q345B galvanized sheet

Thickness: 2.5~3.0mm

Width: 450-476mm

Weight: 65KG

Specifications of products

Product: by product drawing

Product width: 310mm ± 5mm

Product height: 81mm ± 5mm

Product specifications

Forming method: Cold roll forming

Production speed: ≤10m / min

Feeding direction: left feed

Main voltage: 380V, 50Hz

Unit total power: about 20.7KW

Drive shaft bearing: 6026

Turbo lift: SWL10-3 / 23-FU3

Main drive motor: YVP180M-4-15

Reducer: ZQ500-48.57

Wallboard material: A3

Shaft material: 40

Mold material: Gcr15

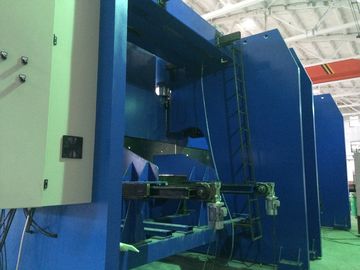

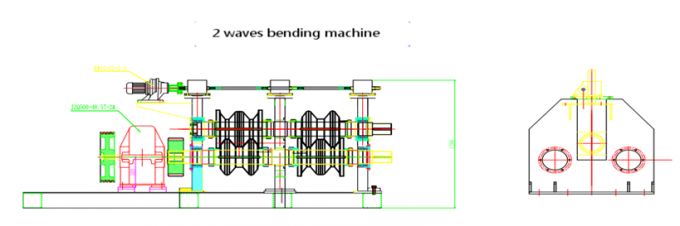

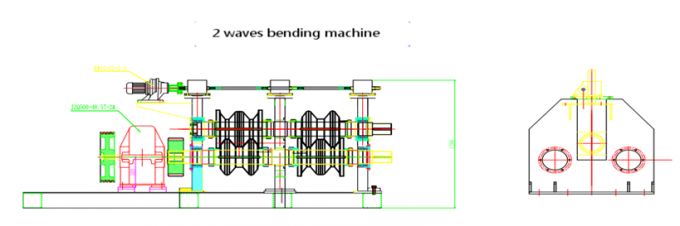

II, Overview of equipment structure

The equipment frame is processed by A3 steel plate, after aging treatment, 3-roller structure, 1 upper and 2 lower, the lower roller adopts a fixed structure, the upper roller adopts slider movement adjustment, and 3 sets of turbine box drive are driven by the motor to adjust the upper and lower The turbine box is connected by a connecting rod to ensure the synchronization of 3 sets of boxes, and the 3 independent wall plates are connected by a shaft to ensure the parallelism of the whole machine. The diameter of the roller shaft is 110mm. There are two sets of molds on the left and right, one for the inner arc and one for the outer arc, and a set of 15KW main motor. It is driven by a ZQ500 reducer, which drives the left and right lower shafts through gears.The gear module is 10m, one for each left and right.The product is processed through the operation console.

III, Equipment configuration checklist

| No |

Part Name

|

Quantity

|

| 1 |

Forming mould

|

One set of molds on each side

|

| 2 |

15KW drive motor

|

1Set

|

| 3 |

Forming mold shaft

|

3Sets

|

| 4 |

Turbo lift

|

3Sets

|

| 5 |

Lifting drive motor

|

1Set

|

| 6 |

ZQ500 reducer

|

1Set

|

| 7 |

Electrical console

|

1Set

|

| 8 |

Equipment anchor bolt

|

1Set

|

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!