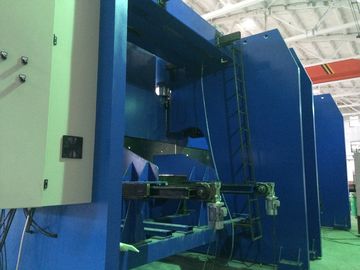

6x2000 508mm-760mm Steel coil slitting line

Description:The series production is used for the metal plate decoiling, slitting and winding into several volumes needed width coil plate. Suitable for processig of cold rolled and hot rolled carbon steel,silicon steel, tinplate, stainless steel and the surface of all kinds of metal plate after plating. The Slitting Line PLC control, human-machine interface, according to a high degree of automation,simple operation and reliable.

Detail of all the device:

1. Hydraulic coil loading dolly

This dolly can carry steel coil and make it move up and down .Four-wheel guide rail walking, up and down is finished by hydraulic cylinder, the running of the dolly is finished by motor and gearbox reducer.

2. Hydraulic decoiler

Double-head umbrella type, Including:left and right unit,

Open and close: Hydraulic

It consists of guide styled base, bracket, arrester mechanism, decoiling shaft and umbrella type double-head.

The decoiler can move from left to right and centralize simultaneously.

3.Light type Hydraulic press-guide, shovel head, opener, pinching mechanism:

It composed of frame-styled base, hydraulic press-guide arm, hydraulic shovel-head mechanism, hydraulic opener mechanism, hydraulic pinching mechanism etc.

3.1 Hydraulic press-guide mechanism: It consists of hydraulic pressing-guide arm, pressing-guide steel wheel, sprocket wheel& chain transmission mechanism, equipped with 5.5Kw cycloid pinwheel speed reducing motor etc.

3.2 Hydraulic shovel-head mechanism: It consists of shovel-head shell, hydraulic shovel-head, shovel-head hydraulic lifting& balance mechanism etc.

3.3 Hydraulic opener mechanism: It consists of guide pillar and guide sleeve, hydraulic opener press-down& lifting mechanism etc.

3.4 Hydraulic pinching mechanism: It consists of bracket, sliding block base, 2 pinching rolls, upper roll hydraulic lifting& press-down mechanism , power parts, gearbox. etc.

4.Tansition worktable,length:3m

5. Rough leveling unit

6. Guiding device before slitting

Guiding device consists of working bracket, guide rail, screw mandrel adjusting& centralizing mechanism, active guide base stage, vertical roller mechanism.

All the device before the slitting unit.

7.Slitting unit:

It consists of mainframe part and power part.

Power part:It consists of power base, decelerator, AC speed-adjustable motor, gear distribution case, coupling, clutch, connection pieces, universal cross transmission etc.

Mainframe part:It consists of base stage, fixed-style bracket,big sliding block of blade shaft, blade shaft two pieces, active bracket, sliding block of tool shaft, active bracket hydraulic entry &exit blade-changing adjusting mechanism, upper tool shaft electric lifting &press-down adjustable mechani, etc.

8. Scrap rewind mechanism:

It consists of bracket, rewinding shaft, bearing base, 2 cone rewinding disks, chain& sprocket wheel transmission mechanism, reducer, coupling, motor etc.

The rough leveling unit has three rollers for leveling function. It is inactive mode.

9. Looping &transition worktable:

It consists of bracket, bearing base, rollerway, supporting plate,

Looping pit Length×width×depth: as technical parameter

transition worktable, with hydraulic cylinder for rising up.

It is including left and right two parts.

10. Pre-separation, tension mechanism, hydraulic press- seperation mechanism, plate-supporting mechanism:

It consists of base, bearing base, pre-seperation bearing, damping bracket, damping plate, damping plate hydraulic lifting& press-down mechanism, tension reverting bracket, 2 tension reflector rolls, press-seperation bracket, press-seperation shaft, press-seperation, hydraulic press-down& lifting mechanism, hydraulic plate-supporting mechanism, hydraulic plate-supporting lifting& balance mechanism, equipped with seperation sheets, nylon spacer bushes etc.

11. Recoiling unit:

It consists of base, recoiling reducing gear case, recoiling shaft, arch plate, expansion-keeping disk, diagonal sliding block expansion& retraction mechanism, hydraulic mouth of tongs clipping mechanism, expansion &rotatary oil cylinder mechanism, arrester mechanism, coupling, hydraulic active supporting arm, supporting base, equipped with AC speed-adjustable motor etc.

12. Hydraulic unloading dolly:

This dolly can carry seperated-coil, hydraulic move and lift, the running of the dolly is driven by motor four-wheeled guide track move out the line and exit.

13. Electrical system:

Central control table.

It consists of cabinet, main electrical control operating cabinet, assistant operating cabinet and other electrics. Slitting and recoiling motor.

The equipment set safety protection, emergency stop& power-cut button, machine-halt dispaly lamp etc.

14 Hydraulic system:

Hydraulic power 25L/min

Including:hydraulic station, valves, oil tank, joint, soft pipe, hard pipe and so on.

Slitting blade, spacer, space plate, spacer barrel, rubber ring list( not With machine, need additional cost)

Application:

This line is for steel coil uncoiling, plate slitting and coil steel slitting process

Technical Parameter:

-

Raw material max. thickness 6mm , Min. thickness 2.5mm. hot rolled mild steel.

-

Width of material:800-1550mm

-

Weight of steel coil:Max 25 tons

-

Inner diameter of steel coil:508mm-760mm

-

Outer diameter of steel coil:Max.2000mm

-

Pinch roller diameter: 190mm

-

Pinching roller motor power: 2.2kw, gearbox model: BWD13, rate:187

-

Pinching roller working speed : 3m/min

-

Rough leveling roller quantity : 3 , up one , bottom two.

-

Rough leveling roller diameter: 125mm

-

For slitting finish products, slitting width tolerance: ±0.20mm

-

For slitting finish products, Max.weight of coil: 15ton

-

For slitting finish products, The steel coil inner diameter: 760mm

-

Slitting unit thickness: 2.5~4.5mm, C245

-

Looping pit specifications: 5500×2200mm×2500mm Length×width×depth

-

Slitting shaft diameter: 220mm

-

Slitting shaft material:40Cr

-

Slitting unit main motor power: 37kw (960RPM), GEAR BOX650

-

Details of blade , spacer, rubber ring , see attachment list.

-

Slitting blade material: H13K, Hardness HRC55-58

-

Scrap rewind mechanism main motor power: YLJ6.3KG/M

-

Rewinding speed, thickness 4.5mm, max. 20m/min. thickness 2.5mm, max. 25m/min AC frequency speed adjustable

-

Rewinding unit main motor power: 90kw(960rpm), gearbox: 850

-

Details of dimension ,see attached drawing

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!