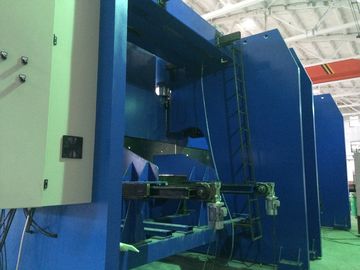

High Mast Assembly Straightening Machine

Model: HJZ-1800

(for Monopole, High mast, 5G pole)

高杆合缝校直机 型号:HJZ-1800

(适合于电力杆,5G基站杆,高杆灯等)

应用范围:

- 主要适合于电力杆,5G基站杆,高杆灯杆等直径比较大,厚度比较厚的杆子.

- 功能1:部分杆子的纵向焊接后的杆子校直.

- 功能2:在折弯后,通过上面和侧面油缸将2片拼合起来,再通过手工进行点焊,便于下一道焊接工序的进行.

- 功能3:为焊接后的杆子整圆,便于装配法兰.

Application:

Mainly suitable for Monopole, smart poles, 5G poles, power poles and highmast pole, with large diameter and thicker thickness.

Function 1: Straighten some pole after longitudinal welding.

Function 2: After bending, the two pieces are joined by the upper and side cylinders, and then spot welding is performed manually,

which is convenient for the next welding process.

Function 3: It is a complete circle for the welded pole, convenient for assembling the flange.

主要技术参数MAIN TECHNICAL FEATURES

| No. |

项目Item |

单位Unit |

规格Value |

| 1 |

型号Model |

|

HJZ-1800

|

| 2 |

适合高杆灯杆,电力杆的最大直径

Max diameter of pole

|

mm |

1800 |

| 3 |

顶部油缸工作力Working force |

KN |

1200 |

| 4 |

顶部油缸最大行程 Max stroke |

Mm |

850 |

| 5 |

顶部油缸活塞杆与下台面最大距离

Max. distance from rod to worktable

|

Mm |

1800 |

| 6 |

两侧缸顶出力 Two-side cylinder output force |

KN |

300X2

|

| 7 |

侧缸行程 Lateral cylinder stroke |

mm |

600 |

| 8 |

两侧缸上下移动距离 Movement distance from upper to lower for two-side cylinder |

mm |

900 |

| 9 |

液压最大工作压力 Max working pressure |

MPa |

21 |

| 10 |

工作台距底面高 Height above ground of worktable |

mm |

650 |

| 11 |

立柱内宽 Column inner distance |

mm |

2000 |

| 12 |

主电机功率(双泵) Main motor power |

kW |

15+5.5 |

| 13 |

机器重量 Main part Weight |

kg |

19000 |

| 14 |

机器占地Machine space |

mm |

27000*3500*4100 |

| |

|

|

|

技术说明:Technical explain:

1, 本机为三梁工作台结构,油缸安装于上横梁中央,上下运行.

2, 两侧油缸按装于主机两侧面, 侧缸通过一对长行程的油缸,工具杆子直径作上下运行,调整油缸的作用点和杆子中心一致.

3, 所有动作均为点动即按住相应的按钮即有相应的动作,松开后即停止,两侧缸可同时动作也可分别动作..

4, 在机器的工作台前后位置按装两套托轮装置,可以上下升起,以方便杆子前后移动.

5, 在机器的工作台前后位置按装两套旋转装置,可以上下升起,使杆子旋转.

6, 托轮装置和旋转装置升起,全部为液压装置, 力量大,稳定可靠.

7, 主机位置有4个小油缸,控制之间位置的滚轮.

8, 主油缸, 侧面油缸单独油路,互不干涉,不会失压.

9, 带无线遥控操作手柄,

10, 聚胺脂覆盖防止压痕

1. This machine is a three beam worktable structure, with the main hydraulic cylinder installed in the center of the upper crossbeam and running up and down.

2. The two-side hydraulic cylinders are installed on both sides of the main body, and the side cylinders run up and down through a pair of long stroke hydraulic cylinders. The position is adjusted to align the action point of the side cylinder with the center area of the pole.

3. All actions are jog, which means holding down the corresponding button will cause the corresponding action, and releasing it will stop. The two cylinders can act simultaneously or separately.

4. Install two sets of supporting wheel devices at the front and rear positions of the machine's workbench, which can be raised up and down to facilitate the movement of the pole forward and backward.

5. Install two sets of rotating devices at the front and rear positions of the machine's workbench, which can be raised up and down to rotate the pole.

6. The supporting wheel device and rotating device are raised, all of which are hydraulic devices with strong force, stable and reliable.

7. There are four small hydraulic cylinders at the host position, which control the position of the rollers between them.

8. The main oil cylinder and the side oil cylinder have separate oil circuits that do not interfere with each other and will not lose pressure.

9. Equipped with a wireless remote control joystick,

10. Polyurethane coating to prevent indentation.

Spare parts with machine:

One more sets wireless remote control handle

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!