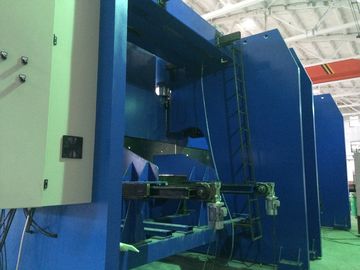

CNC POLE SHUT- WELDING MACHINE, Model: HM2500/12000

数控收口直缝焊管机, 型号: HM2500/12000

设计专用于5G杆, 电力杆, 高杆灯杆

Designed for highmast pole, monopole, 5G communication pole

直径范围:400~2500mm, 厚度:6~20mm, 长度:12000mm

Diameter range:400~2500mm, Thickness:6~20mm, Length:12000mm

双弧双丝埋弧焊机

double arc three wire welding machine

使用范围:适用于大长度的中杆纵向自动收口焊接,5G杆,电力杆,高杆灯杆

Application scope: suitable for large length medium size pole (like 5G pole, monopole, high mast pole) longitudinal automatic closing welding

CNC POLE SHUT-WELDING MACHINE, it is suitable for one shell or two shells type polygonal and circle taper pole(Conical pole).

it is automatic welding line, the gantry type structure is fixed and with welding system, V-shaped fully pole length dolly(worktable) with servo

motor for speed adjustable moving, The hydraulic cylinder push the clamping wheel to close the pole and do welding at same time.

For two seams pole, when first seam welding finished, the bottom roller will rise and rotate the pole to another seam position to start second

seam welding.

此机通常适用于焊接多边形和圆形锥形中型尺寸的杆子, 可以是一片型也可以是两片型的. 本焊机是自动焊接线, 小车配有可调速伺服电机, 可以牵引杆子运动.液压油缸促使压轮收紧中杆,同时进行焊接.

两片型的杆子,当一条缝焊接完成后, 滚轮装置顶起杆子旋转到位, 完成另外一条焊缝的焊接.

专有特点 Proprietary features:

- 数控自动调整,数控系统,随着杆径变化,自动调节压力, 自动调节压脚位置,自动匹配料速度和位置,保持焊缝始终处于合拢状态,以确保焊接顺利进行.

CNC automatic adjustment, CNC system, with the change of pole diameter, automatically adjust the pressure, automatically adjust the

presser foot position, automatically match the feeding speed and position, keep the welding seam always in the closed state, to ensure

the smooth welding.

- 特殊的数控系统使得左右脚同步性能非常好

- Special CNC control system makes the left and right side of the foot synchronization performance is very good.

- 确保在前工序合格的基础上,焊接后,杆子焊缝无扭转,机器后边无需人员撬扭杆子来对中焊缝.

- On the basis of the qualification of the previous process, after welding, there is no torsion of the pole weld, and there is no need for personnel to pry and twist the rod at the back of the machine to center the weld.

4. 杆子在V型工作台上,其运动为伺服控制,以保证头尾焊接的稳定性.从头焊到尾,大大降低尾部未焊接的长度.

The pole is on the V-shaped worktable, and its motion is servo controlled to ensure the stability of head and tail welding.

Welding from head to tail greatly reduces the length of the tail that is not welded.

- 压脚数量为3套, 优点是减少压脚对路灯杆表面的压力, 表面美观, 减少压痕影响, 同时适合生产八角杆, 多棱杆和圆锥杆.

- 可以是等径的也可以是圆锥的.

The number of clamping roller is 3 sets, the advantage is reduce the roller pressure to the pole surface, and reduce the scratch on the surface. It is suitable for the production of octagonal pole, polygonal pole and conical pole. It can be equal diameter or conical.

- V型工作台可以快速电动回到设定位置,降低操作人员的劳动强度.

The V-shaped worktable(dolly) with motorized fast returning back function, and it reduces the labor intensity of operators.

- 埋弧焊功能Submerged arc welding function

- 带杆子后导向板,自适应调整,实际操作中很少调节焊缝位置,降低操作人员的劳动强度.

With pole back guiding device,it can be adjusted adaptively. In practical operation, the position of welding seam is seldom adjusted,

which reduces the labor intensity of operators.

- 通过安装在机头上的摄像头,把焊缝反映到控制台上的屏幕上,使得焊缝的跟踪简单容易,降低操作人员的劳动强度.

Through the camera installed on the machine head, the welding seam is reflected on the screen of main control panel, making the

tracking of the welding seam simple and easy, and reducing the labor intensity of the operator for monitoring of the welding.

- 自主研发的油压和控制同步系统,降低了对杆子的要求,使得焊接后的杆子圆整,变形小.

- The self-developed oil pressure and CNC system, making the welded pole round and deformation small.

- 当两片型的杆子,一条缝焊接完成后,滚轮装置顶起杆子旋转到位,完成另外一条焊缝的焊接.

- For two seam pole, when first seam welding finished, the bottom roller will rise and rotate the pole to another seam position to start second seam welding.

- 前侧上下料 loading and unloading in the front position

- 内衬铜块带水冷系统, 提高焊透率

- The inner copper blocks, which greatly improves the welding penetration rate. Copper block contains cooling water.

- 操作人员:1人.Operator: 1 person.

- 大于10mm板厚,采用双弧双丝(或者双电三丝)埋弧焊,直流+交流, 直流焊采用大电流低电压,直流电弧获得大熔深,交流采用相对较小的电流大电弧电压,增加熔宽,获得美观的焊缝成型.焊接速度增加一倍,提高焊缝性能,降低电力消耗.

Optional items: for plate thickness greater than 10mm, adopt double arc and double wire (or double electric and three wire) submerged

arc welding, DC + AC, DC welding adopts high current and low voltage, DC arc obtains large penetration, AC adopts relatively small

current and high arc voltage, increases fusion width, and obtains beautiful weld formation. Double the welding speed, improve the weld performance and reduce the power consumption.

- 可选项目:联网生产数据系统

- 功能1:可以向生产管理人员提供生产数据:开机通电时长,焊接时长,非焊接时长,生产数量等.

- 功能2:软件的及时更新,获得最优最新的软件和经验数据,可以协助客户,远程故障诊断,远程参数调整.便于客户快速恢复生产.

Optional item: networked production data system

Function 1: it can provide production data to production management personnel: power on time, welding time, non welding time,

production quantity, etc

Function 2: timely update the software to obtain the best and latest software and experience data, which can assist customers in

remote fault diagnosis and remote parameter adjustment. It is convenient for customers to quickly resume production.

机器包含以下部分

The machine consists of the following parts:

- 伺服驱动的V型工作台 Servo driven V-type worktable (Dolly)

- 用于V 工作台的前后路轨 Front and rear rails for V table

- 主龙门架 Main gantry frame

- V型工作台驱动 Drive system for V-type worktable

- 液压夹紧部分 Hydraulic clamping Unit (包括压紧轮, Including clamping rollers)

- 埋弧焊系统,带焊丝送料系统 Submerged arc welding system, with wire feeding system

- 焊剂回收系统 Flux recovery system

- 内衬铜块带水冷系统 Inner copper bar with water cooling system

- 操作平台 Operating platform

- 滚轮架子2对, Pole rotation Roller, 2 pairs

- 液压系统 Hydraulic system

- 控制系统 Control system

| 技术参数Technical parameter |

| 1 |

可焊接杆的直径范围

Diameter of pole

|

400-2500mm |

| 2 |

可焊接灯杆的最大长度

Worktable length

|

12000 mm |

| 3 |

可焊接杆厚度Thickness of pole |

6~20mm, Q235, Q355 |

| 4 |

压脚数量

Clamping feet quantity

|

3 units. 3套 |

| 5 |

油泵电机功率

Motor power of oil pump

|

2.2+2.2+3 KW |

| 6 |

移动电机功率

Servo motor power for V-type worktable (dolly)-

|

7KW.速度可调节

Speed adjustable, AC servo

|

| 7 |

垂直顶压行程

Vertical pressing stroke

|

2500mm |

| 8 |

操作高度

Operating height

|

杆子下角到地面的距离

The distance from the bottom angle of the pole to the ground:800

|

| 9 |

焊机

Welding machine

|

双电三丝埋弧焊机

直流埋弧焊电源型号 1250

输入电源 AC380V,三相,50Hz

额定输入容量 80KVA

输出电流 DC250A~DC1250A

额定负载持续率 80%

交流埋弧焊电源型号 1000A

额定输入容量:125KVA

输入电源 AC380V,单相,50Hz

电压输出范围:30~44V

输出电流 AC250A~AC1250A 额定负载持续率 60%

双电三丝焊机品牌:开元

Double electric three wire submerged arc welding machine

DC submerged arc welding power supply model 1250

Input power AC380V, three-phase, 50Hz

Rated input capacity 80KVA

Output current dc250a ~ dc1250a

Rated load duration 80%

AC submerged arc welding power supply model 1000A

Rated input capacity: 125kva

Input power AC380V, single phase, 50Hz

Voltage output range: 30 ~ 44V

Output current ac250a ~ ac1250a, rated load duration 60%

Double electric three wire welder brand: Kaiyuan

|

| 10 |

焊丝直径

Welding wire diameter

|

双电三丝:单丝:4.0, 双丝: 2x2.0 (1.6)

Double power three wire: single wire: 4.0,

double wire: 2x2.0(1.6)

|

| 11 |

焊接工作速度

Welding speed

|

0.3~1.5m/min 无级可调 (注:厚度不同,速度也不同)

0.3~1.5m/min stepless adjustable

Note: different thickness, different speed)

|

| 12 |

焊接方向Welding direction |

焊接从大端向小端焊接

Welding from big end to small end

|

| 13 |

焊透率Welding penetration rate |

80~90% |

| 14 |

电器元件

Electrical components

|

施耐德 法国品牌

Schneider (French brand)

|

| 15 |

数控系统CNC system PLC |

Siemens (Germany brand) |

| 16 |

液压泵主电机品牌Brand of main motor of hydraulic pump |

皖南电机

WNM

|

| 17 |

小车电机

V-type worktable (Dolly) motor

|

伺服电机

SERVO MOTOR

|

| 18 |

焊机品牌

Welding machine brand

|

如上第9条, as item 9

开元 (Kaiyuan) Top brand in China

|

| |

|

|

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!