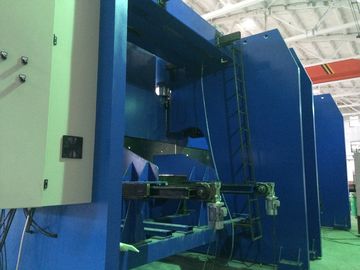

CNC LASER LIGHT POLE DOOR CUTTING MACHINE, MODEL : LDC-350/2000

数控激光路灯杆电门切割机,型号:LDC-350/2000

(适合圆杆,棱杆for round, conical pole, octagonal pole and polygonal pole)

Application: 应用

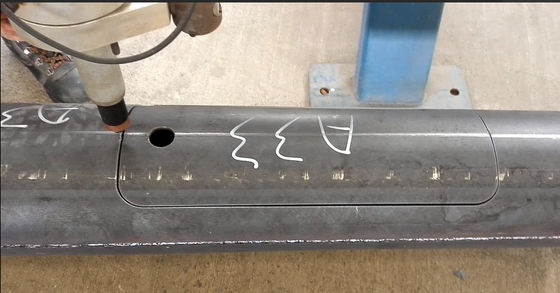

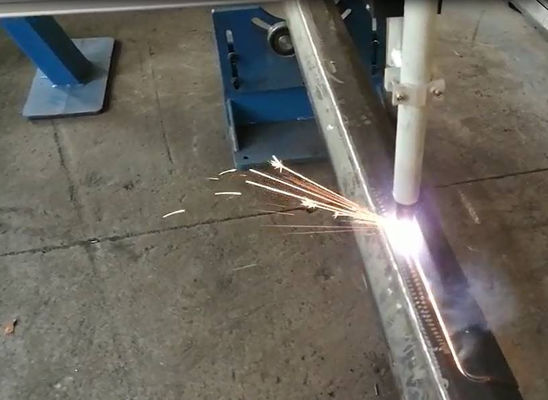

It is suitable for conical pole, round pole, octagonal light pole door CNC cutting, cutting shape can be any which draw designed by computer.

The cutting source is automatic laser, so the cutting speed is much fast, and cutting edge quality is better than plasma and flame cutting.

The key point is that, Due to using laser cutting way, the cutting gap is very small, and the cut pieces are generally used as door covers.

适用于圆锥形杆,圆杆,八角形灯杆电门的数控切割,切割形状可以是任何电脑CAD 可以绘制的图形都可以通过随机附带的专用软件来切割.

切割源是自动激光,因此切割速度会很快,并且切口光滑圆整,切口质量比等离子和火焰切割更好.

由于使用激光切割方式,切割缝隙比较小,切割下来的部件通常可以作为门盖使用.

Main parameter:主要技术参数

| No. |

Item |

Parameter |

| 1 |

Pole material 杆子材质 |

Steel 钢 |

| 2 |

Max. cutting length, X axis

最大切割长度,x轴

|

2000mm (for once stroke cutting) |

| 3 |

Rotation angle, A axis

旋转角度, A轴

|

Any angle 0~360 degree |

| 4 |

Minimum pole outer diameter 最小杆子直径 |

60 |

| 5 |

Maximum pole outer diameter 最大杆子直径 |

350 |

| 6 |

Max weight of pole 最大杆子重量 |

350kg |

| 7 |

Max length of pole 最大杆子长度 |

12m,14m |

| 8 |

CNC control system数控系统 |

方菱异形管数控系统L6000

Fangling L6000

|

| 9 |

Fiber Laser source 激光光源 |

锐科激光器

Raycus 3KW

|

| 10 |

Laser cutting torch 激光头 |

E do 2.0 |

| 11 |

Laser height adjuster激光调高器 |

iHC100B |

| 12 |

Laser height adjusting system激光升降模组 |

MS-J150 |

| 13 |

Laser cooling device 激光冷水机 |

HL-2000-QG2/2 |

| 14 |

建议使用气体,氧气

Suggestion of cutting gas: O2

|

O2 |

| 15 |

Cutting thickness and speed

切割厚度和速度参考

|

见附件 |

| 16 |

Cutting Gap |

Around 0.3-0.5mm |

| 17 |

Main motor/Brand 电机 |

Servo motor 伺服 |

| 18 |

Control axis 控制轴 |

3 axis, X,A,Z 3轴数控,X,A,Z |

| 19 |

Working mode: as assembly line type, left in and right out, one way production direction

工作形式: 流水线型式,左进右出, 一个生产方向

|

The poles waiting for cutting are placed on one side of the machine in a row, and the finished poles are moved to the other side of the machine in a row. Labor saving, fast loading and unloading.等待切割的灯杆有序放在机器一边,切割完成的灯杆有序移动到机器另一边.节约人工,上下杆速度更快. |

| 20 |

Environmental temperature 环境温度 |

0-45℃ |

| 21 |

Humidity 湿度 |

<90%, no condensation无凝结 |

| 22 |

Surroundings周边环境 |

Ventilation, no big shake 通风,无大的震动 |

| 23 |

Input voltage 输入电压

(Can be customized according to buyer’s country voltage requirement.)

可以按照客户方的国家电压提供

|

单相Single phase, 220V, 50HZ

三相Three phases, 380V, 50HZ

|

Cutting thickness and speed切割厚度和速度参考

|

厚度mm

Thickness

|

切割气体

Gas

|

切割速m/min.

Cutting speed

|

功率w

Power

|

气压bar

Gas pressure

|

切割高度mm

Height of Nozzle

|

| 2 |

O2 |

5.5-6.5 |

3000 |

0.7~0.9 |

0.4 |

| 3 |

O2 |

3.8-4.5 |

3000 |

0.7~0.9 |

0.4 |

| 4 |

O2 |

3.3-3.6 |

3000 |

0.7~0.9 |

0.4 |

| 5 |

O2 |

3-3.3 |

3000 |

0.5~0.7 |

0.4 |

| 6 |

O2 |

2.9-3.1 |

3000 |

0.5~0.7 |

0.4 |

| 8 |

O2 |

1.2~1.3 |

3000 |

0.7~0.9 |

0.4 |

| 10 |

O2 |

1.1~1.2 |

3000 |

0.7~0.9 |

0.4 |

| 12 |

O2 |

0.9~1.0 |

3000 |

0.9~1.1 |

0.4 |

CNC control system Fangling L6000方菱异形管数控系统L6000

|

iMC6610

运动控制器

iMC6610

Motion controller

|

电机控制

Motor control

|

6路高速脉冲输出伺服驱动器,位置模式,最高频率3MHz,

含焦点轴控制,包含6路编码器反馈

6-way high-speed pulse output servo driver, position mode, maximum frequency 3MHz,

Including focal axis control and 6 way encoder feedback

|

|

每轴独立伺服报警和使能

Each axis has independent servo alarm and enable function

|

|

运动控制性能

Motion control performance

|

控制周期1ms

Control cycle: 1ms

|

|

S型加减速

S-shaped acceleration and deceleration

|

|

贝塞尔曲线拟合算法

Bessel curve Fitting algorithm

|

|

激光控制信号

Laser control signal

|

2路PWM信号,可选择24V或5V

2 way PWM signal, 24V or 5V

|

|

4路DA0~10V模拟量输出

4 way DA0~10V analog output

|

|

总线接口

bus interface

|

2*RS232,2*RS485,1*RS422,2*CAN |

|

网络接口

network interface

|

2*RJ45 |

|

IO信号

IO signal

|

32路输入,含轴限位输入口,低有效.

32 way inputs, including axis limit input interface, low effective.

|

|

32路输出,高有效

32 way outputs, high effective

|

|

供电

Power

|

直流24V,3A

DC 24V,3A

|

|

系统工作环境

working condition

|

温度-20 ℃至+60 ℃;相对湿度0-95% 无凝结

Temperature range: -20 ℃ to +60 ℃;

Relative humidity 0-95%

No condensation

|

|

iHC100B

激光调高器

iHC100B

Laser height adjuster

|

电机控制

Motor control

|

模拟量伺服驱动器,速度模式

Analog servo driver, speed mode

|

|

IO信号

IO signal

|

上下限位 + 2 路输入 + 2 路输出

Upper and lower limits+2 way input + 2 way output

|

|

接口

interface

|

和轴卡网络通讯

Communicate with the axis card network

|

|

供电

Power

|

直流 24V,2A

DC 24V,2A

|

单腔光纤激光器

Laser generator : Raycus 3KW

光学特性 optical characteristics

| 功率 Power |

3000W |

| 波长范围 Wavelength |

1080±10 nm |

| 光纤芯径 Output fiber core diameter |

25μm /50μm |

| 光缆长度 Cable Length |

12 m 或定制/12 m or Customized |

| 输出连接器 Beam Delivery |

QBH 或定制/QBH or Customized |

| 指示光 Guide Beam |

红色/Red |

| 工作模式 Operation Mode |

连续或调制/Continuous or Modulated |

| 偏振方向 Polarization |

随机/Random |

| 输出功率稳定度(25℃) Power Stability |

<±1.5% (2h) |

| 功率调节范围 Power Adjustment Scope |

10%-100% |

| 最大调制频率 Max. Modulation Frequency |

5kHz |

| 机械尺寸及重量 |

| 重量 Weight |

<35Kg |

| 机身外形尺寸 Outline Feature |

80mm*402mm*346mm |

| 电学特性 |

| 电压 Voltage |

220±20V,AC,PE,50/60Hz |

| 功耗 Power Consumption |

6.0 kW |

| 控制方式 Control Interface |

RS232 |

| 水冷参数 |

| 制冷量需求 Mini. Water Cooling Capacity |

4.5 kW |

| 设置温度 Temperature Settings |

25℃ (激光模块,Laser Module),30℃(QBH)

|

| 水管尺寸(外径) Cooling Tubes Size (External) |

Φ12mm |

| 冷却水流量 Cooling Water Flux |

>20L/min |

|

QBH 冷却水流量

QBH discharge of Cooling Water

|

1.5~2.0L/min |

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!