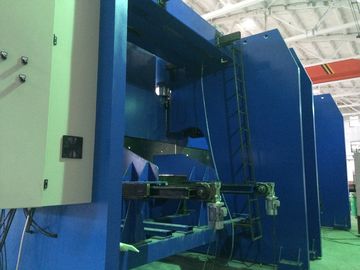

Synchronized hydrualic multi- machine CNC tandem Press Brake / bending machine

Quick Detail:

| Name |

Other name |

Brand Name |

CMC |

| CNC Hydraulic Press Brake Machine |

Bending Machine

Press Brake

Light pole bending

Two bending machine

|

Feature |

Two Press Brake machines can work together to bend long length for light pole, such as 12m, 14m, 16m |

| Advantage |

Two raster displays installed at both sides of ram to control cylinders |

Controller system |

We give customer several options: Netherlands brand: Delem DA-52

DA-65W

|

Description:

1. The frame of machine is composed of tank, worktable, left and right housings and

ram. So it has high strength and good rigidity. Also it takes vibration to eliminate

stress.

2. Synchronization working principal of both machines:Adopting electric-hydraulic

proportional valve to ensure the synchronization of both machines. The proportional valve is made by BOSCH company with very good performance such as small friction between mechanic action pairs, fine electronic amplifier and electric magnet with high controlling force and continuous action. There are two raster displayers on both sides of machine to inspect the position of ram continuously and feed back the signal to control system, then the control system will control electric-hydraulic valve to make two cylinders synchronization on one machine. Because the raster displayers are installed to “C” plates, not on housing plates directly, the deflection of ram and frame when working will not effect its measuring and controlling precision. When two machines working together, the differential potentiometer installed between two machines will transfer the mechanic synchronizing signal into electronic one and feed back to synchronization plate and control system. The signal will be enlarged by BOSCH amplifier to control the synchronization of both machines by controlling electric-hydraulic proportional valve. So the synchronization of two machines is achieved with high precision.

3. Through computer,the operator could communicate with machine. The computer has several service language, calculate and adjust the bending force automatically. Also it could calculate and control the dead point, speed changing point.The strokes (Y1, Y2) of ram could make a small tilt to meet the special requirement of user.

4. Equipped with good guiding system, position measuring system and hydraulic balance system to meet the requirements of full length job and eccentric job.

5. Worktable compensation unit is adopted to make up for deflection of machine when working to make sure the precision of work piece.

6. The surface of cylinder has good wearing and heat treatment, so it has good lubrication and long service life.

Specifications

Communication with customers

A. what does this multi-press brake machines do?

B: Usually, these big and long press brake machine are used to produce light pole and ship. As you see, the light pole on the two side of road is very tall, it can be 12m, 14m, 16m, even much higher. And also for the ship, the ship manufacturer need to make ship body, some part is very big. One of Ship Company bought our 3000T tandem press brake machine, that one is our max during the history.

A. How many and which country have purchased your company multi- press brake machines?

B: We have exported to many countries, In India, there our 4 lines; In Algeria, 2 lines, In USA, 1 line…..In China, there are many small press brake machine manufacturers, but for big machines, only several companies have this technical ability to produce

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!