CNC Tandem Press Brake Enhances Long-Part Bending Accuracy for Infrastructure Projects Worldwide

The expansion of global infrastructure projects is fueling demand for CNC Tandem Press Brakes, particularly in regions investing in transportation, renewable energy, and industrial construction. From high-speed rail networks in Asia to offshore wind farms in Europe, tandem press brakes are delivering the long-part bending capabilities required for modern engineering.

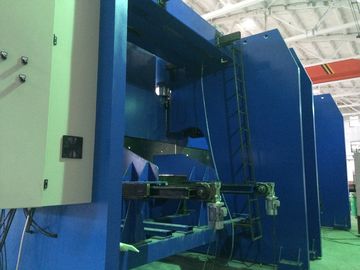

A CNC Tandem Press Brake system synchronizes multiple bending machines into one continuous unit, enabling manufacturers to process oversized metal sheets with precise control. This technology is now widely adopted in China, India, Germany, and the Middle East, where mega infrastructure projects demand consistent bending accuracy.

In India, CNC tandem press brakes are being used to manufacture metro rail coaches and bridge components. Fabricators in Maharashtra and Gujarat report reduced setup times and enhanced bending repeatability.

In the Middle East, particularly in Saudi Arabia and the UAE, CNC tandem press brakes are supporting fabrication for oil and gas infrastructure, stadium construction, and urban development projects. Their ability to bend thick plates for large steel frames makes them indispensable for heavy-duty applications.

European engineering firms in Denmark and Spain rely on CNC tandem press brakes for wind energy tower sections. These machines ensure uniform bending across long steel panels, meeting stringent quality standards for renewable energy components.

In North America, infrastructure modernization programs in Canada and the United States have led to increased procurement of CNC tandem press brakes. States like New York and California are using tandem systems to fabricate bridge reinforcements and structural steel profiles.

Technological innovations such as servo-hydraulic synchronization, laser angle measurement, and CNC adaptive control have transformed tandem press brakes into precision machines. These features allow automatic compensation for material springback and thickness variations.

As governments worldwide invest in infrastructure modernization, the CNC Tandem Press Brake continues to play a critical role in delivering the large-scale, high-precision metal components required for 21st-century development.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!