CNC Tandem Press Brake Drives High-Precision Metal Fabrication in Global Manufacturing Hubs

As global demand for large-format sheet metal fabrication continues to rise, the CNC Tandem Press Brake is emerging as a core technology across major industrial regions including North America, Europe, and Southeast Asia. From automotive frames to aerospace panels and structural steel components, manufacturers are increasingly turning to tandem press brake systems to achieve superior bending accuracy, efficiency, and scalability.

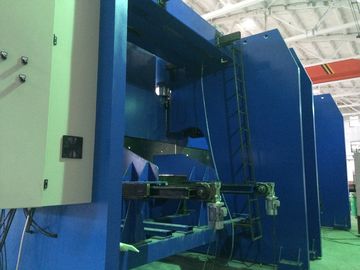

A CNC Tandem Press Brake consists of two or more synchronized press brakes controlled by a single CNC system. This design allows operators to bend extra-long or oversized metal sheets—often exceeding 8 meters in length—without compromising precision. Industries in Germany, the United States, Japan, and China are leading adopters of this technology as infrastructure, renewable energy, and heavy equipment manufacturing continue to expand.

Manufacturers in Texas, Ohio, and Michigan have reported productivity increases of up to 40% after upgrading to CNC tandem press brake systems. “With tandem control, we can handle longer steel profiles in a single setup," said a metal fabrication manager in Chicago. “That reduces repositioning errors and labor costs."

European factories in Italy and Poland are also investing heavily in CNC tandem press brakes to support rail transportation and construction projects. These systems enable multi-axis bending with automatic crowning, real-time angle compensation, and programmable backgauge control, making them ideal for high-volume production.

In Asia, particularly in China’s Guangdong and Jiangsu provinces, CNC tandem press brakes are being deployed to meet export demand for construction machinery, shipbuilding components, and renewable energy infrastructure. Chinese manufacturers are now offering CE-certified and UL-compliant machines to serve overseas markets.

With built-in Industry 4.0 compatibility, modern CNC tandem press brakes can integrate with ERP and MES systems, allowing real-time monitoring and predictive maintenance. This has proven especially valuable in manufacturing clusters across Singapore, South Korea, and the UAE.

As global manufacturing centers modernize, the CNC Tandem Press Brake is rapidly becoming a standard investment for companies seeking high-precision bending of long metal parts. Its role in boosting production efficiency, reducing scrap, and supporting smart factory initiatives makes it a critical asset for metal fabricators worldwide.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!