CNC Tandem Press Brake Adoption Accelerates in North American and European Fabrication Plants

The CNC Tandem Press Brake is seeing rapid adoption across North America and Europe as manufacturers seek advanced solutions for bending long and heavy metal sheets with extreme accuracy. From automotive suppliers in Detroit to infrastructure contractors in Germany, tandem press brakes are redefining modern sheet metal processing.

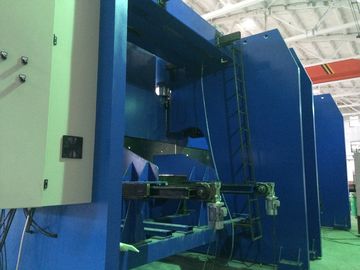

Unlike single press brake machines, CNC tandem systems synchronize two or more hydraulic or servo press brakes into a unified bending line. This enables the bending of large steel plates used in bridges, wind towers, ship hulls, and railcars—applications that are common in industrial regions like Canada, the United Kingdom, and Scandinavia.

In the United States, states such as Texas, California, and Ohio are leading investment in CNC tandem press brakes as part of broader automation initiatives. “We upgraded our bending line to a tandem configuration to handle 12-meter structural beams," said a fabrication company owner in Houston. “It improved throughput and minimized manual handling risks."

European manufacturers are following suit. Germany, France, and Italy are expanding their press brake capacity to support renewable energy projects, including wind turbine towers and solar frame systems. CNC tandem press brakes offer programmable multi-axis bending, laser angle measurement, and adaptive crowning to ensure perfect results even on thick or high-strength steel.

In Eastern Europe, particularly Poland and the Czech Republic, government-backed industrial upgrades are driving demand for CNC tandem press brakes. These machines support export-oriented production for automotive and heavy machinery markets.

Asia-Pacific regions, including Australia and South Korea, are also adopting CNC tandem press brakes to support mining equipment manufacturing and shipyard fabrication.

With advanced CNC controls, modern tandem press brakes feature touchscreen HMIs, cloud-based diagnostics, and AI-driven bending optimization. These smart features are especially appealing to manufacturers in high-cost labor markets like Japan and Switzerland.

As manufacturing becomes increasingly globalized, the CNC Tandem Press Brake is becoming an essential tool for fabricators seeking competitiveness, consistency, and long-term productivity gains across regional and international markets.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!