CNC Tandem Press Brake Boosts Structural Steel Production in Texas, USA

A large structural steel fabrication company based in Houston, Texas, recently upgraded its bending line with a CNC Tandem Press Brake to meet increasing demand from infrastructure and commercial construction projects.

The company specializes in producing long steel beams, columns, and support frames for highways, warehouses, and high-rise buildings. Their existing single press brake system struggled with oversized sheets exceeding 10 meters, leading to frequent repositioning, inconsistent bending angles, and higher scrap rates.

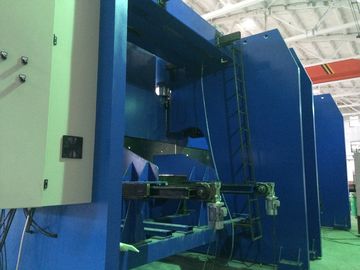

After evaluating multiple solutions, the company invested in a two-unit CNC tandem press brake system with synchronized CNC control, automatic crowning, and a multi-axis backgauge. The installation allowed the fabrication team to bend long steel plates in a single setup.

Within three months of commissioning, production efficiency improved by 38%, while material waste dropped by 22%. The CNC tandem press brake delivered uniform bending accuracy across long profiles, eliminating secondary corrections and manual adjustments.

“Our old process required two operators to reposition long parts multiple times," said the production manager. “With the CNC tandem press brake, we complete each part in one continuous bending operation."

The system was integrated with the factory’s ERP platform, enabling real-time production tracking and predictive maintenance. This digital connectivity helped reduce unplanned downtime by 15%.

As a result of the upgrade, the company secured two new contracts for bridge reinforcement components and steel framework for logistics centers. The CNC tandem press brake played a critical role in improving throughput, quality consistency, and delivery reliability.

This project highlights how CNC tandem press brake technology is driving competitiveness for metal fabricators in the United States, particularly in high-demand construction regions such as Texas and California.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!