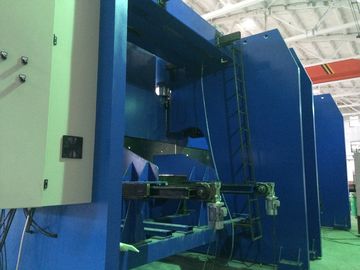

Bolts and nuts hot dip galvanizing automatic production line

Production Capacity: 8000~10000 ton/year

Production line technology key points:

The project is consist of three system, is automatic hot dip galvanizing, environmental control system, logistical system, total project is based on environmental protection, energy saving and reduce manpower.

Key technology:

1.A project of fully automatic environmental protection hot galvanizing production line

2. Auto logistical control system, can go on real time adjustment according to production beat, use resource efficiently.

3. furnace adopts clean energy to heat zinc pot, furnace temperature automatic control, prolong the service life of zinc pot

4.All waste gas collection closed, centralized treatment and discharging standard, zero emission.

Technical parameters

1. Zinc pot size:non-ferrous pot, ceramic pot 4×1×1m, capacity is about 26t.

2. Output: 8000~10000 ton/year

3. Type of heating: electrical heating

4.Work shift: 3 shift(8 hours/shift, year working time 300 days,3 shifts,day working time 20h)

5.Layout:loop shape, three across span is 6.5m, length is 36.4m,details in layout plan. (or according customer side situation , can be straight line type , L type ,C type)

6. Electric and water

6.1 The max power of electrical equipments is about 500Kw.

6.2 In average 1ton production need 0.01m3 water, the pressure can't lower than 0.2MPa.

6.3 The PH level of water is 6.5 to 8, tap water, river water or well water is adoptable, mainly for supplementing consumption during production.

7. Environmental protection treatment system: waste gas and waster solid treatment for producing healthily.

8. Compressed air: bleed pressure 0.6Mp/cm2, air demand 6m3/h.

System layout

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!