CNC YAG Laser cutting machine 500W 1500 X 3000 for sheet metal

1. Effect chart of cutting sample processing

Advertising words, Sheet metal processing, Work piece cutting

2. Features

2.1 High precision: Be applicable to cutting on precision parts and kinds of art words and charts.

2.2 Fast speed:It is 200 times more than line cutting.

2.3 Small heat affection, not easy to deformation. Cutting seam is flat and beautiful, no need for subsequent processing.

2.4 High price ratio: The price is one third of the similar performance CO2 laser cutting machine, and two fifths of the same effect CNC machine.

2.5 Low cost: It is only one eighth to one tenth of the same CO2 laser cutting machine. The cost is USD 4.8-6.4 per hour. The cost of CO2 laser cutting machine is USD 24-38.4 per hour.

2.6 Low subsequent maintaining cost: It is only one tenth to one fifteenth of the same CO2 laser cutting machine, and one third to one fourth of the same effect CNC machine.

2.7 Stable function guarantees the continuous production. Solid YAG laser is one of the most stable and mature products in the laser area.

2.8 Advantages compared with the CNC machines:

(1) It can finish the processing of kinds of complicated structure. It can cut any shape drawn on the computer.

(2) No need to open mode. The product will be done as soon as the chart is drawn on the computer. It can develop new products quickly and reduce the cost.

(3) It has automatic tracing system, so it can do both the flat cutting and the rugged surface cutting.

(4) CNC machines can’t meet the complicated technical requirements, but laser cutter can.

(5) Smooth surface and high level products, that CNC machines can’t do.

(6) The shape formed box (within the thickness of 0.5m) needs the device which can do with holes and grooves. CNC machines can’t do with it, but YAG-3015 laser cutting machine can solve it.

3. Applied material

Applicable to cutting on plate or tube in stainless steel, carbon steel, alloy steel, spring steel, aluminum, copper, titanium, etc. It has excellent processing effect on kinds of hard brittle alloy steel.

4. Application Fields

Widely used in sheet metal processing, metal ware, kitchen appliance, high-resolute device, electric control box, auto parts, glasses, posters, crafts, lighting, and precise parts.

5. Equipment characteristics and technical advantages

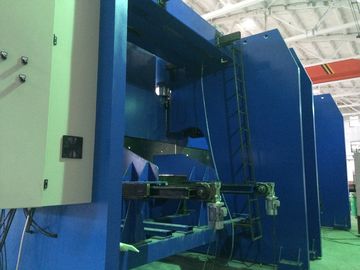

YAG-3015 laser cutting machine is achieved by powerful laser focused on object to cause instant melting and evaporation, with xenon lamp as the generator. Automatic cutting is controlled by digitalized mechanic system. This machine has condensed the technologies of laser, digital, and precise mechanics.

- Split type designed and independent operation table. It can be moved according to the condition. Comfortable and easy operation.

- Imported servo motor working table, traveling area 1500mm*3000mm.

- Laser head can be adjusted through the Z axis, traveling area 0-120mm

- Strong cutting ability: 500W type can stainless steel cut up to 4mm.

- Low cutting cost: It can cut with air, and its cost is USD 2.4 – 3.2. The exact cost includes electricity 13-15 degrees per hour, light source lamp USD 0.288-0.32 per hour, lens protection USD 0.08 - 0.16 per hour, and no any other costs. If you use O2 or N2, The cost should be increased by USD 1.6 – 1.92. (As the shape and thickness are different, the gas consumption will be different.)

- Fast cutting speed, high efficiency, safe operation, and stable performance.

- Good quality, small distortion smooth and fine look outside.

- Imported servo motor and gearing system to guarantee precise cutting. High cutting precision.

- Dedicated software enables graphic or text to be instantly designed or processed. Flexible and easy operation.

- The laser beam is easy to realize in time or space spectrophotometer. It can do multiple beams processing at the same time or multi-station order processing.

6. Equipment components

It is mainly made up of pulse YAG laser, pulse laser power, laser cooling system, external light path system, controlling system, etc.

1,System structure

| Item |

Name |

Quantity

(piece)

|

Remarks |

| 1 |

Pulse YAG laser |

1 |

U.S. special technology structure mental torch |

| 2 |

Laser electric controller |

1 |

Electrically controlled high-frequency pulse |

| 3 |

Special cooling system |

1 |

Special laser equipment |

| 4 |

Optical system

Speed expansion lens

Spectroscope

Focusing lens

|

1 |

Adopts German technology and special designed. Optical lens directly affect the quality of facular, the affect the quality of cutting seam and flange, cutting speed and thickness. |

| 5 |

Imported servo motor |

1 |

Imported Panasonic servo motor and imported screw and rails from Taiwan |

| 6 |

Controlling system |

1 |

CNC |

| 7 |

Laser indication system |

1 |

Semiconductor(Red light) |

The main equipments in order to improve the technical performance of solid laser cutting machine are laser electric controller, laser torch and optical lens. The three parts decide the laser technical level of cutting machine. We realize that the cutting technical performance stands in the leading position in Asia by the innovation of the three parts.

2,Main equipment

| Main components |

Simple descriptions |

Remarks |

| Laser |

American technical laser torch |

Part A shall not remove the factory sealed of 600W type by himself without the authority of part B. |

| Laser power |

Pulse laser power |

Special YAG cutter |

| CNC operation table |

It adopts steel structure welding, the stress failure processing, heavy duty rack structure, Imported rolling screw TBI, liner rail HIWIN, and Panasonic servo motor. |

It has assistant equipment of discharging, tightly pressing and blanking. |

| Controlling system |

FLSK F-7500 |

|

| Nesting Software |

InteGNPS |

|

| Cooling system |

Double circulation system, temperature alarm, flow protection and water level protection. |

Power frequency 7P |

| Height Controller |

HYD CNC-300 |

|

3, The main technical parameter:

| Technical indicators |

Technical parameters |

| Wave length |

1064nm |

| Max. laser power |

500W |

| Pulse width |

0.2~20ms continuously adjustable |

| Pulse frequency |

1~500Hz continuously adjustable |

| Positioning |

Red light indication |

| Effective processing area |

1500mm*3000mm |

| X/Y axis repeated positioning accuracy |

±0.03mm |

| Supporting photo format |

DXF, DWG, PLT, etc(supporting Auto CAD software,Corel draw software) |

| Total power consumed |

≤ 30KW |

| Power supply |

3 phases,4 wires, AC, 380V,50Hz,60A |

| Overall dimension(L×W×H) |

4560mm×2450mm×1560mm |

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!